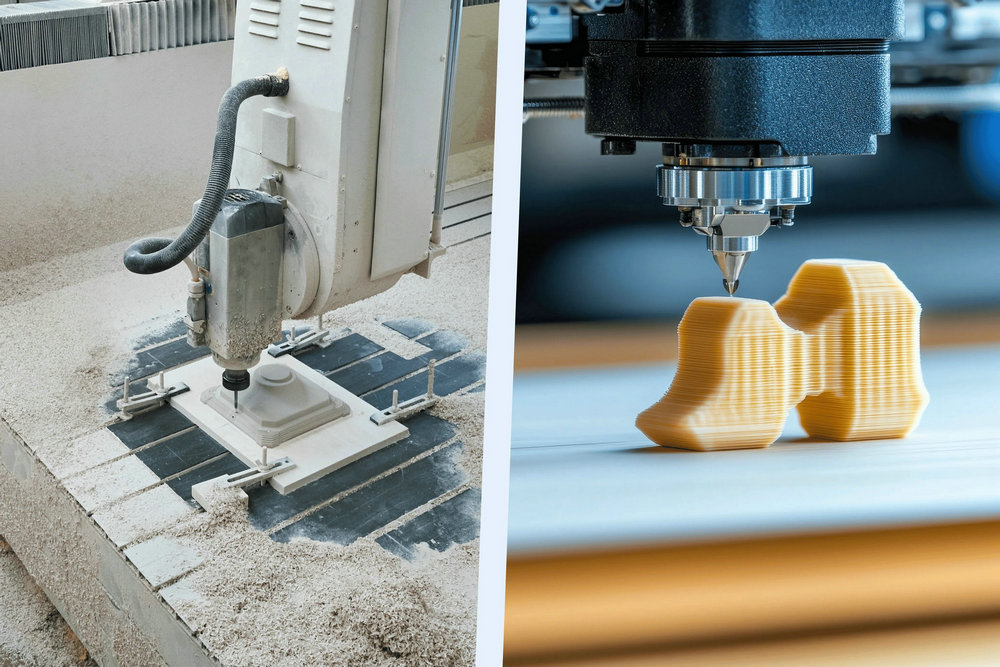

In the realm of contemporary architecture, where innovation dances with functionality, precision CNC cutting has emerged as a game-changer for the crafting of architectural panels. Imagine a process where digital precision intersects with artistic vision, allowing for intricate designs and flawless finishes that were once considered unattainable.

Architects and builders alike are reaping the rewards of this cutting-edge technology, as it not only streamlines production but also enhances the aesthetic appeal of structures. The ability to create complex geometries with utmost accuracy means that imagination has no limits; every curve, every angle, and every detail can be brought to life.

As we delve into the manifold advantages of precision CNC cutting, it becomes clear that this technique is not just a mere tool—it’s a transformative force shaping the future of architectural design. Join us as we explore how this remarkable technology is revolutionizing the industry, one panel at a time.

Enhanced Design Flexibility

Precision CNC cutting revolutionizes the landscape of architectural panel design, offering an unprecedented level of flexibility that traditional methods simply cannot match. Imagine the ability to create intricate patterns, unique shapes, and bespoke sizes that align perfectly with your vision, all while maintaining impeccable precision.

This technology empowers architects and designers to push boundaries, allowing for bold creative expressions that can adapt to the most complex project specifications. It enables the transformation of materials into eye-catching features, ranging from striking facades to functional elements, all tailored for specific environments.

With CNC cutting, the possibilities are practically limitless; the only constraint is the imagination, making it a pivotal tool in the pursuit of innovative architectural solutions.

Superior Precision and Accuracy

Precision CNC cutting delivers unmatched levels of accuracy that are vital for architectural panels, where every dimension and detail matters immensely. The intricate capabilities of CNC machinery enable it to achieve tolerances as tight as a few thousandths of an inch, something traditional cutting methods struggle to replicate.

Imagine a beautiful façade, where each panel fits seamlessly together, creating a harmonious overall design; this is made possible through precise machining. Moreover, the ability to automate complex cuts reduces human error, ensuring that each piece meets the exact specifications required by architects and designers.

With such meticulous attention to detail, not only do these panels enhance the aesthetic appeal of structures, but they also significantly streamline the installation process, as they arrive ready to fit perfectly into place. The fusion of artistry and engineering, thus, transforms visions into reality with undeniable precision.

Improved Material Utilization

Precision CNC cutting revolutionizes the way architectural panels are produced, leading to significantly improved material utilization. By employing advanced technology that meticulously calculates every cut, waste is minimized and resources are optimized.

This precision not only reduces the amount of raw material required but also allows for intricate designs that were previously deemed unfeasible. Imagine transforming an entire sheet of material into beautifully crafted components with almost zero excess.

Furthermore, this efficiency translates into cost savings, allowing architects and builders to invest more in innovative features rather than surplus materials. When every inch counts in design, the ability to maximize materials without compromising on aesthetics is a game changer.

It’s not just about cutting shapes; it’s about crafting a smarter, more sustainable future in architecture.

Conclusion

In conclusion, the integration of precision CNC cutting into the production of architectural panels revolutionizes the construction and design industries by offering unparalleled accuracy, efficiency, and customization. This advanced technology not only enhances the aesthetic appeal and structural integrity of architectural projects but also significantly reduces material waste, leading to more sustainable practices.

By incorporating CNC wood routing services, manufacturers can achieve intricate designs and detailed finishes that elevate the overall quality of their products. As the demand for innovative and high-quality architectural solutions continues to rise, the benefits of precision CNC cutting will undoubtedly play a pivotal role in shaping the future of architecture and design.